Product classification

Glass fiber reinforced plastic pultruded profile

The main products include: FRP pultruded profiles, FRP pultruded grille, FRP molded grille, FRP molded products and a variety of hand paste products.

Classification:

Telephone: +86-13862763910

Product Details

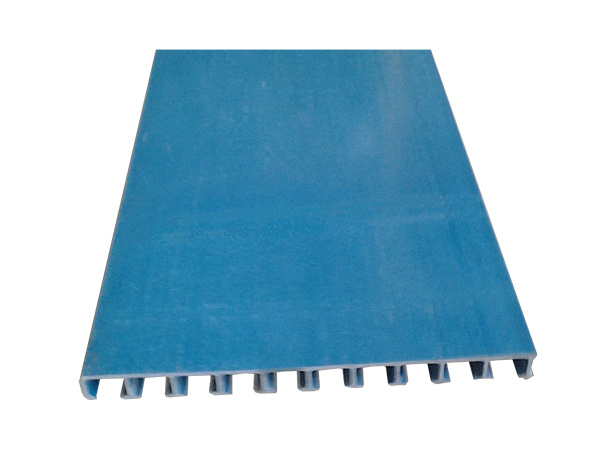

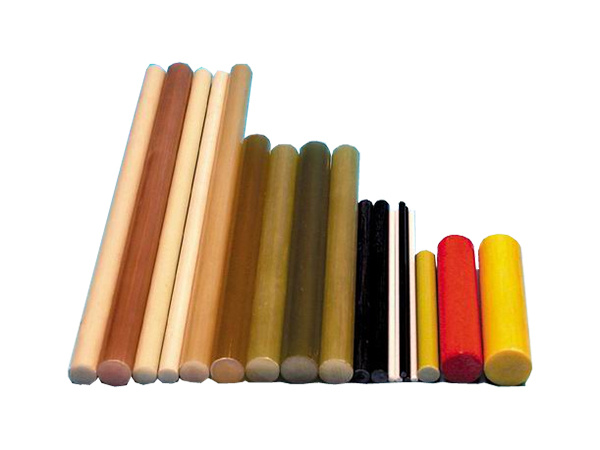

FRP pultrusion profile is a continuous production process that produces FRP profiles with the same cross-section of any length. The reinforcing material used in the fiberglass pultrusion profile can be glass fiber yarn, continuous mat, multi-axial cloth, carbon fiber, etc. After the reinforcement material is dipped in the dipping tank, it is introduced into the mold through the guide device for heating and forming, pulled out by the traction equipment at the other end, and cut into products of different lengths as required.

Performance parameters of pultruded profiles

|

Performance |

Direction |

Unit |

Test Method |

Profile |

Bars |

|

Tensile strength |

Longitudinal (LW) |

MPa |

ASTM D638/GB1447-83 |

210-350 |

500-700 |

|

|

Transverse (CW) |

MPa |

|

30-60 |

|

|

modulus of elasticity in tension |

Longitudinal (LW) |

GPa |

ASTM D638/GB1447-83 |

15-28 |

32-42 |

|

|

Transverse (CW) |

GPa |

|

5-7 |

|

|

bending strength |

Longitudinal (LW) |

MPa |

ASTM D790/GB1449-83 |

210-390 |

600-900 |

|

|

Transverse (CW) |

MPa |

|

60-100 |

|

|

flexural modulus of elasticity |

Longitudinal (LW) |

GPa |

ASTM D790/GB1449-83 |

15-24 |

32-42 |

|

|

Transverse (CW) |

GPa |

|

5-7 |

|

|

Compression strength |

Longitudinal (LW) |

MPa |

ASTM D695/GB1448-83 |

220-350 |

400-450 |

|

|

Transverse (CW) |

MPa |

|

60-100 |

|

|

compression elastic modulus |

Longitudinal (LW) |

GPa |

ASTM D695/GB1448-83 |

16-23 |

|

|

|

Transverse (CW) |

GPa |

|

5-10 |

|

|

short beam shear strength |

Longitudinal (LW) |

MPa |

ASTM D2344 |

25-35 |

|

|

Poisson's ratio |

Longitudinal (LW) |

mm/mm |

ASTM D3039 |

0.3-0.4 |

|

|

barbard hardness |

|

-- |

ASTM D2583 |

40-50 |

50 |

|

relative density |

|

-- |

ASTM D792 |

1.7-1.9 |

1.85-1.95 |

The advantages of pultruded profiles:

1, corrosion resistance, anti-aging;

2. Light weight and high strength;

3. Flame retardant;

4 non-magnetic, non-conductive

Products have passed the ASTME 84 fire test and the American Classification Society quality certification. Under the strict quality control of the production process, the product pass rate of up to 99.8, has passed the 1S09001:2008 quality system certification.

Type of glass fiber roving selected

| Code | Roving type | Recommended use occasions |

| E | alkali-free roving | Applied to high strength requirements and high corrosion resistance occasions |

Selected packing type

| Code | Packing type | Recommended use occasions |

| ATH | aluminum hydroxide | Flame retardant, smoke suppression, corrosion resistance occasions |

| PR | No filler, pure resin | For high corrosion resistance occasions |

| Grid thickness (mm) |

Rib back thickness (up/down) |

Square Dimensions (mm) |

Overall plate size (mm) |

Weight (kg/m2) |

Opening rate (%) |

| 30 | 7.0/6.0 | 26 × 26 52 × 52 |

1530 × 4000,1532 × 4050 | 15.3 | 60 |

| 38 | 6.0/5.0 | 26 × 26 52 × 52 |

1150 × 4011 | 19.5 | 60 |

Key words: FRP pultruded profile, FRP pultruded grid, FRP molded grid, FRP molded products, hand lay-up

Keyword:

Previous Page

Next Page

Thank you for your attention to Nantong Shengrui composite materials

Please send us your business needs, we have a professional service team to answer you!

More products

Explore more products>Service Hotline

Address: Group 8, Luyao Village, Chengbei Street, Rugao City, Jiangsu Province, China.

Mailbox: info@frp-sr.com

Telephone: +86-513-87381658

Fax: +86-513-87386399

QQ: 2408947102

Copyright © 2023 Nantong Shengrui Composite Material Co., Ltd.